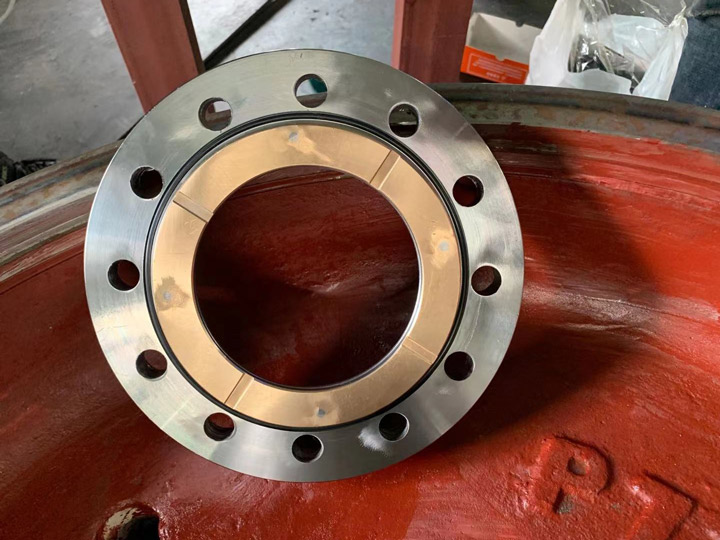

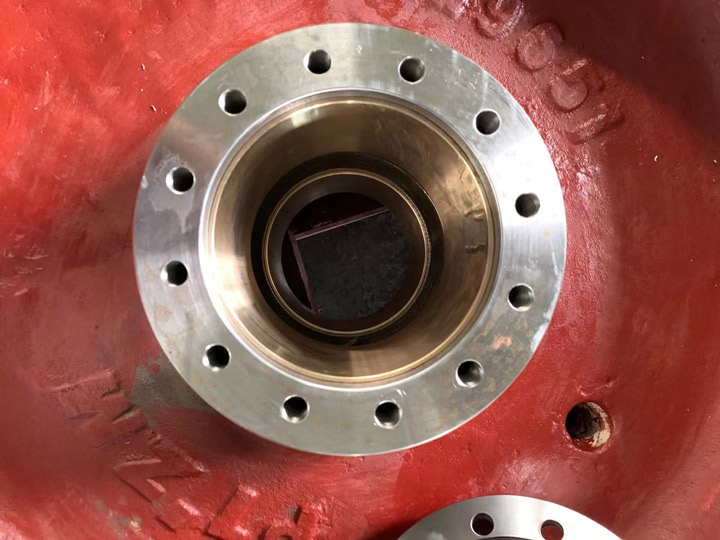

D11 BULLDOZER FRONT IDLER ASSEMBLY 9W9651-CATERPILLAR

Caterpillar D11 idler is made of a specific material to fully distribute the load and tension;They are induction hardened, the track and support roller are made of special steel, which is precisely ground, and induction hardened, the track plate, plus heat treatment.

The advantages of our D10 Idler are mainly as follows

D11 idler body of our product is made of 35SiMn with a hardness of HRC55-58 and the deepth reach 6-8mm , which is more wear-resistant. Central shaft material for 42Crmo steel is not easy to fracture. So that the service life of the product is longer.

Our technology uses forging and precision casting, CNC vertical machining production. Precision casting makes the wheel body of high density, no pores and not easy to leak gas. CNC vertical machine is used for more accurate control of product size and higher finish smoothness. And the equipment is better, the operation is safe, the production efficiency is higher,

The technical drawing of the product is 1:1 original size. This will not appear when the customer purchase size deviation can not be installed.

We have a professional QC team, and to follow up the product testing, semi-finished and finished product testing and produce reports.

All products have their own ID number. When customers feedback product problems, we will find the corresponding QC test declaration according to the ID number of the product, find the problem and come up with the solution.

The D11 bulldozer's efficient and resourceful earth-moving equipment is much loved by users. These large bulldozers are designed to be durable, ensuring a long service life.With a modular design that optimizes performance and simplifies performance, the D11 bulldozer achieves more tasks safely, efficiently and excellently at a lower cost. The raised sprocket and undercarriage parts work in tandem to increase traction and give the operator a smoother ride, while the bogie suspension provides up to 15% ground contact. Through regular maintenance of undercarriage parts, so that the machine better serve your work, high-quality replacement undercarriage parts you deserve to have. Please feel free to contact us

| Description: | D11 IDLER GRP-TRACK 9W9651 – Caterpillar |

| Place of origin: | China |

| Brand name: | PT'ZM |

| Brand name: | Caterpillar |

| Model number | D11 |

| Part number | 9W9651 |

| Price: | Negotiate |

| Packaging details: | Fumigate seaworthy packing |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 10000 Sets/month |

| Material: | 35Simn/42Crmo/QT450-10 |

| Technique: | Forging/Precision casting |

| Finish: | Smooth |

| Hardness: | HRC55-58, deepth 6-8mm |

| Quality: | mining operation heavy duty high-end quality |

| Warranty time: | 24 monthes |

| After-sales service: | Video technical support,Online support |

| Color: | Black or Yellow or Customer required |

| Application: | Bulldozer |

D11N, D11R & D11T