Short Lead Time for China Bucket Link Arm Link H Link Engineering Machinery Parts for Excavator and Bulldozer

We know that we only thrive if we could guarantee our combined selling price competiveness and good quality advantageous at the same time for Short Lead Time for China Bucket Link Arm Link H Link Engineering Machinery Parts for Excavator and Bulldozer, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We know that we only thrive if we could guarantee our combined selling price competiveness and good quality advantageous at the same time for China Engineering Machinery Parts, Construction Machinery Accessories, Our company’s main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

The Hitachi EX1200 series undercarriage parts manufactured by PINGTAI is an excellent OEM and aftermarket serve your excavator.When high quality is a requirement and cost reduction is necessary, our products with industry-leading warranties of 6 months to 2 years are your solution.

The material of the EX1200 carrier roller body is forged by 40Mn2. and the surface heat treatment HRC 48-55 depth up to 5-8mm. Precision CNC machine machining size is more accurate

The center shaft of the carrier roller material is 42CrMo and forged .The hardness of surface heat treatment can reach 48-55HRC More wear-resisting . Core hardness of HRC 28 or above is not easy to fracture. Tempering 180 degrees before finishing. The surface of the center shaft of the carrier roller is polished by CNC machine tool to make the shaft smoother.

High sealing aprons are used inside the carrier roller to prevent dirt, sand and water from damaging it.

The carrier roller using friction welding technology welding quality is good and stable, and environmental protection, no pollution.Welding process does not produce smoke or harmful gas, no splash, no lone light and spark, no radiation.Known as the green welding technology of the future.

The function of carrier rollers is to carry the track link upwards, make certain things are linked tightly, and enable the machine to work faster and more steadily . Our products use special steel and produced by new process. Every procedure goes through strict inspection and the property of compressive resistance and tension resistance can be ensured.

|

Description: |

Carrier Roller OEM Manufacturer Heavy duty |

|

Place of origin: |

China |

|

Brand name: |

PT’ZM |

|

Brand name: |

Hitachi |

|

Model number |

EX1200 |

|

Part number |

4638433 |

|

Part number |

9078675 |

|

Price: |

Negotiate |

|

Packaging details: |

Fumigate seaworthy packing |

|

Delivery time: |

7-30 days |

|

Payment term: |

L/C T/T |

|

Price term: |

FOB/ CIF/ CFR |

|

Minimum order quantity: |

1 PC |

|

Supply Ability: |

10000 PCS/month |

|

Material: |

40Mn2/42Crmo |

|

Technique: |

Forging |

|

Finish: |

Smooth |

|

Hardness: |

HRC55-58, deepth 6-8mm |

|

Quality: |

mining operation heavy duty high-end quality |

|

Warranty time: |

24 months |

|

After-sales service: |

Video technical support,Online support |

|

Color: |

Black or Yellow or Customer required |

|

Application: |

Crawler excavator |

|

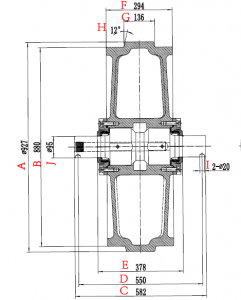

Model |

A |

B |

C |

D |

E |

F |

|

EX1200 |

390 |

195 |

260 |

116 |

240 |

210 |

|

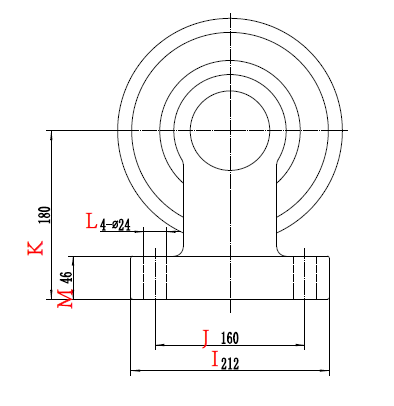

I |

J |

K |

L |

M |

||

|

212 |

160 |

180 |

4-24 |

46 |

EX1200-5, EX1200-5D, EX1200-6

We know that we only thrive if we could guarantee our combined selling price competiveness and good quality advantageous at the same time for Short Lead Time for China Bucket Link Arm Link H Link Engineering Machinery Parts for Excavator and Bulldozer, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Short Lead Time for China Engineering Machinery Parts, Construction Machinery Accessories, Our company’s main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.