China OEM China Komatsu Bulldozer Undercarriage Part D375 Idler Assy Guide Wheel

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for China OEM China Komatsu Bulldozer Undercarriage Part D375 Idler Assy Guide Wheel, Adhering to the business enterprise philosophy of ‘customer first, forge ahead’, we sincerely welcome consumers from at your home and abroad to cooperate with us provide you greatest services!

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for China D375, Komatsu Bulldozer,komatsu bulldozer D375 real idler assy OEM, We’ve got more than 10 years experience of production and export business. We always develop and design kinds of novel products and solutions to meet the market demand and help the guests continuously by updating our solutions. We’ve been specialized manufacturer and exporter in China. Wherever you are, please join us, and together we are going to shape a bright future in your business field!

Komatsu D375 idler is made of a specific material to fully distribute the load and tension;They are induction hardened, the track and support roller are made of special steel, which is precisely ground, and induction hardened, the track plate, plus heat treatment.

The advantages of our D375 idler are mainly as follows

1. D375 idler body of our product is made of 35SiMn with a hardness of HRC55-58 and the deepth reach 6-8mm , which is more wear-resistant. Central shaft material for 42Crmo steel is not easy to fracture. So that the service life of the product is longer.

The materials used in many products on the market are 50Mn and 45# steel, which can not meet the requirements of wear resistance and are easy to fracture.

2. Our technology uses forging and precision casting, CNC vertical machining production. Precision casting makes the wheel body of high density, no pores and not easy to leak gas. CNC vertical machine is used for more accurate control of product size and higher finish smoothness. And the equipment is better, the operation is safe, the production efficiency is higher,

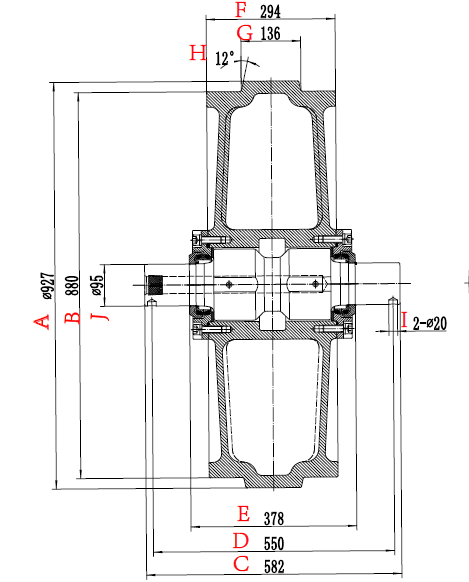

3. The technical drawing of the product is 1:1 original size. This will not appear when the customer purchase size deviation can not be installed.

4. We have a professional QC team, and to follow up the product testing, semi-finished and finished product testing and produce reports.

All products have their own ID number. When customers feedback product problems, we will find the corresponding QC test declaration according to the ID number of the product, find the problem and come up with the solution

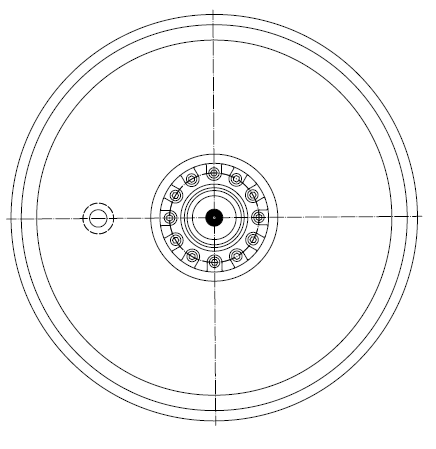

The function of and idler is to guide the track links into running smoothly and to prevent dislocation.Idlers also carry some weight and therefore increasing ther track links decreasing ground pressure.There is also an arm in the center which supports the track link and guides the two sides. The smaller the distance between the idler and track roller, the better the orientation.

|

Description: |

Dozer D375 Front Idler Assembly Manufacturer Mining Equipment |

|

Place of origin: |

China |

|

Brand name: |

PT’ZM |

|

Brand name: |

komatsu |

|

Model number |

D375 |

|

Part number |

195-30-01030 |

|

Price: |

Negotiate |

|

Packaging details: |

Fumigate seaworthy packing |

|

Delivery time: |

7-30 days |

|

Payment term: |

L/C T/T |

|

Price term: |

FOB/ CIF/ CFR |

|

Minimum order quantity: |

1 PC |

|

Supply Ability: |

10000 Sets/month |

|

Material: |

35Simn/42Crmo/QT450-10 |

|

Technique: |

Forging/Precision casting |

|

Finish: |

Smooth |

|

Hardness: |

HRC55-58, deepth 6-8mm |

|

Quality: |

mining operation heavy duty high-end quality |

|

Warranty time: |

24 monthes |

|

After-sales service: |

Video technical support,Online support |

|

Color: |

Black or Yellow or Customer required |

|

Application: |

Bulldozer |

|

Model |

A |

B |

C |

D |

E |

F |

G |

H |

|

D375 |

927 |

880 |

582 |

550 |

378 |

294 |

136 |

12 |

|

I |

J |

|||||||

|

2-20 |

95 |

D375A-2, D375A-3, D375A-5, D375A-6

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for China OEM China Komatsu Bulldozer Undercarriage Part D375 Idler Assy Guide Wheel, Adhering to the business enterprise philosophy of ‘customer first, forge ahead’, we sincerely welcome consumers from at your home and abroad to cooperate with us provide you greatest services!

China OEM China D375, Komatsu Bulldozer, We’ve got more than 10 years experience of production and export business. We always develop and design kinds of novel products and solutions to meet the market demand and help the guests continuously by updating our solutions. We’ve been specialized manufacturer and exporter in China. Wherever you are, please join us, and together we are going to shape a bright future in your business field!