Caterpillar Bulldozer D6D Bottom Roller Double Flange 1181611 Manufacturer

The function of the track roller is to convey the weight of an bulldozer to the ground . When an bulldozer is run on uneven ground, track rollers carry a tremendous impact. Therefore, the support of track roller is huge. Moreover, if it is of poor quality and is often dusty, it needs a very good sealing to prevent dirt, sand and water from damaging it.

The material of D6D track roller body is forged by 40Mn2. and the surface heat treatment HRC 48-55 depth up to 5-8mm. Precision CNC machine machining size is more accurate.

The material of the center shaft of the track roller forged by 42CrMo.The hardness of surface heat treatment can reach 48-55HRC More wear-resisting . Core hardness of HRC 28 or above is not easy to fracture. Tempering 180 degrees before finishing. The surface of the center shaft of the track roller is polished by CNC machine tool to make the shaft smoother.

High sealing aprons are used inside the track roller to prevent dirt, sand and water from damaging it.

The track roller using friction welding technology welding quality is good and stable, and environmental protection, no pollution. Welding process does not produce smoke or harmful gas, no splash, no lone light and spark, no radiation.Known as the green welding technology of the future.

|

Description: |

Bottom Roller Double Flange Heavy Duty Equipment |

|

Place of origin: |

China |

|

Brand name: |

PT'ZM |

|

Model number |

D6D |

|

Brand: |

Caterpillar |

|

Parts number: |

1181611 (DF) |

|

Parts number: |

1181620 (SF) |

|

Price: |

Negotiate |

|

Packaging details: |

Fumigate seaworthy packing |

|

Delivery time: |

7-30 days |

|

Payment term: |

L/C T/T |

|

Price term: |

FOB/ CIF/ CFR |

|

Minimum order quantity: |

1 PC |

|

Supply Ability: |

10000 PCS/month |

|

Material: |

40Mn2/42Crmo |

|

Technique: |

Forging |

|

Finish: |

Smooth |

|

Hardness: |

HRC48-55, depth 5-8mm |

|

Quality: |

mining operation heavy duty |

|

Warranty time: |

24 months |

|

After-sales service: |

Video technical support, Online support |

|

Color: |

Yellow or Black or Customer required |

|

Application: |

Crawler bulldozer |

|

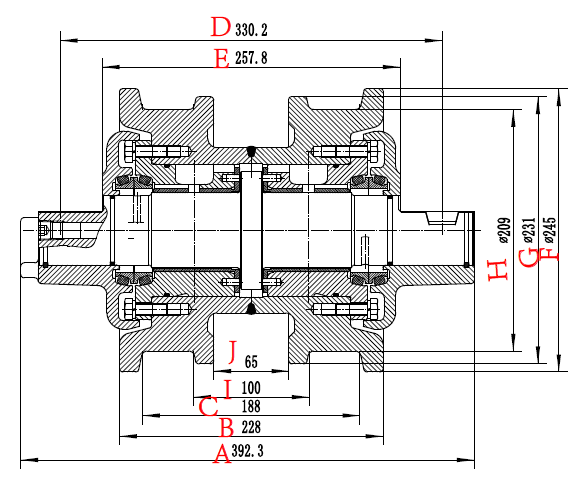

D6D |

A |

B |

C |

D |

E |

F |

G |

|

|

392.3 |

228 |

188 |

330.2 |

257.8 |

245 |

231 |

||

|

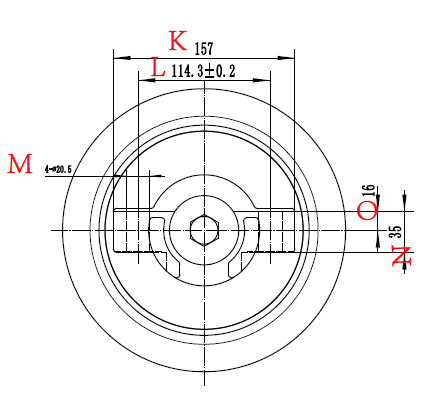

H |

I |

J |

K |

L |

M |

N |

O |

|

|

209 |

100 |

65 |

157 |

114.3 |

4-20.5 |

35 |

16 |

D6, D6B, D6C, D6C LGP, D6D, D6D LGP, D6E, D6F, D6G, D6H, D6H Extended Frame, D6H Fine Grading, D6H LGPD, D6H XL, D6H XR, D6K LT, D6M LGP, D6M XL, D6N LGP, D6N XL, D6R, D6R LGP, D6R XL, D6R XR, D6R XW, D6T D6T LGP, D6T XL, & the D6T XW