Bolt & Nut Mining Operation

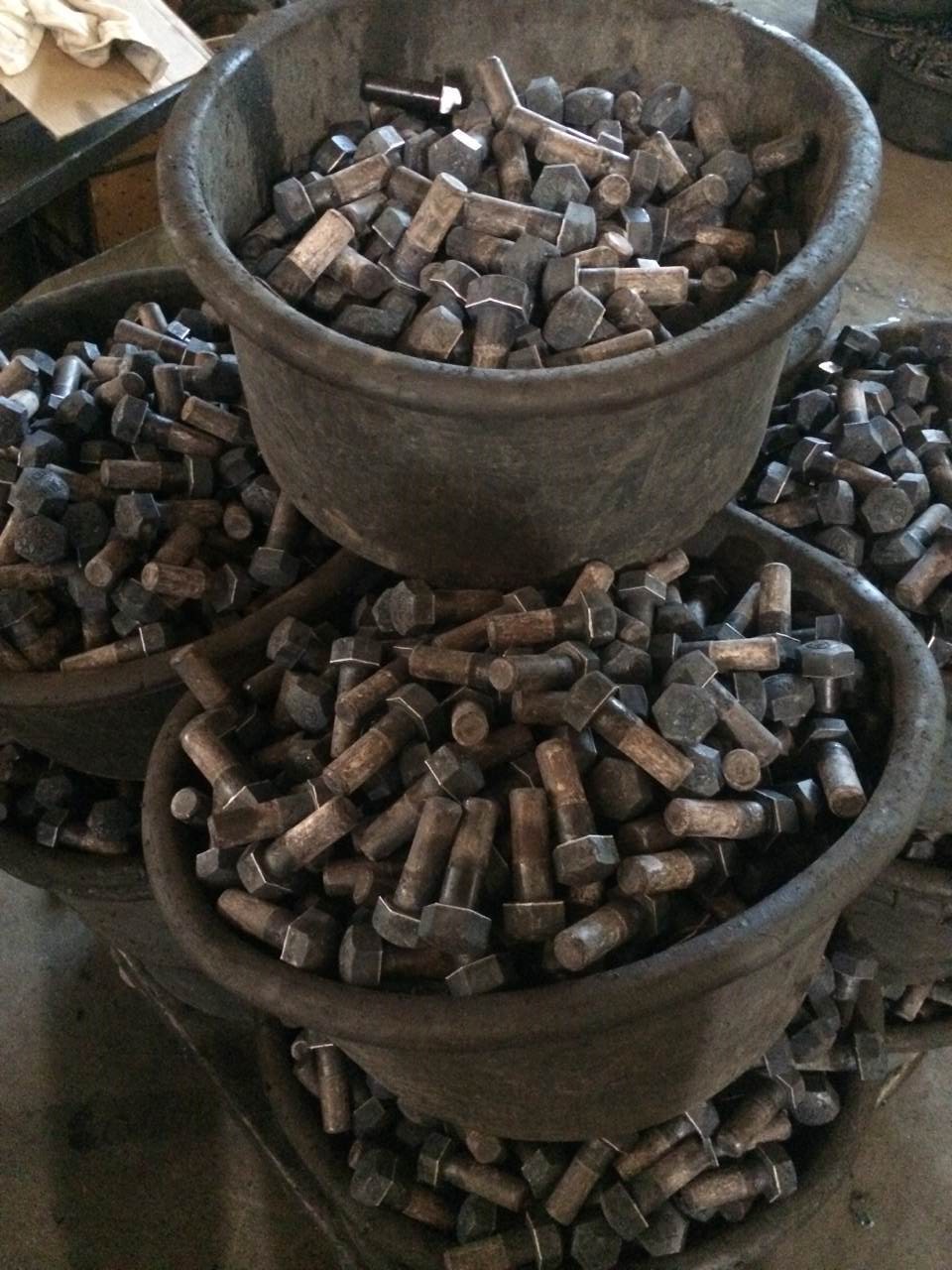

Material using 35 forging, and modulation heat treatment processing technology to make the height of the screw and nut with the clearance more closely, not loose, wear-resistant, more tensile and compression resistance, not easy to break deformation, longer service life. The screw has two kinds of UNF and UNC and the tensile strength and compressive strength can reach 8.8-12.9.

| Product detail information | |

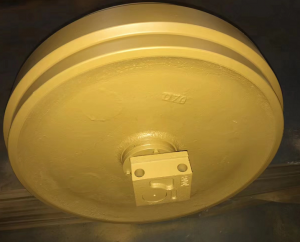

| Description: | BOLT & NUT MINING OPERATION |

| Place of origin: | China |

| Brand name: | PT'ZM |

| Model number | D11 |

| Price: | Negotiate |

| Packaging details: | Cartons and palltes |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 100000 PCS/month |

| Material: | 35CrMo |

| Technique: | Forging |

| Finish: | Zinc(Yellow,White,Blue,Black),Hot Dip Galvanized(HDG),

Black,Geomet, |

| Hardness: | 8.8-12.9 |

| Quality: | mining operation |

| Warranty time: | 1 YEAR |

| After-sales service: | Video technical support,Online support |

| Color: | Yellow or Black or Customer required |

| Application: | Bulldozer & Crawler excavator |

1.The screw is manufactured using 35Crmo forging wire in advance into a spiral shape.Because the wire will deform and become thicker after being forged,We need to choose a wire rod that is slightly thinner than the shaft of the screw when making the screw。

2.The material is conveyed to the appropriate length position and straightened by machine equipment, then it is fed to a cold heading machine.

3.First, the first punch movement makes the wire ready to form, and then the second punch movement again forging the wire and forming its finished product. In cold heading processing, the number of fixed dies (die) and stamping (flatten) dies (punch) is not the same.Some complex screws may need more than one punch with the forming, which requires a multi-station equipment can make the screw forming.

4.After the movement of the punch, the head of the screw has been completed, but the part of the screw shaft has no thread. The forming method of the screw thread tooth is to rub the wire.Rub thread is the use of two relatively rotating screw teeth engraved with thread pressing die (rub plate) extrusion through the middle of the multi-station or punching machine processing cylindrical blank.

5.After starting and rubbing the teeth, the whole screw has been produced. Of course, in order to make the appearance of the screw brighter and better performance, the surface treatment process will be generally done.Such as stainless steel screw cleaning passivation, carbon steel screw surface plating, etc.Made into various colors of screw fasteners

6.In the production of screw fasteners, it should be noted that each screw needs to use different molds, so non-standard screws will need to open another mold for production.

You are a trader or a manufacture?

We are an industry and trade integration business, our factory located in Quanzhou.We are a modern enterprise specializing in the integration of construction machinery and equipment parts manufacturing and network sales.

How Can I Be Sure The Part Will Fit My Excavator?

Give Us Correct Model Number/Machine Serial Number/ Any Numbers On The Parts Itself Or Measure The Parts Give Us Dimension Or Drawing.

How About The Payment Terms?

We Usually Accept T/T Or L/C. Other Terms Also Could Be Negotiated.

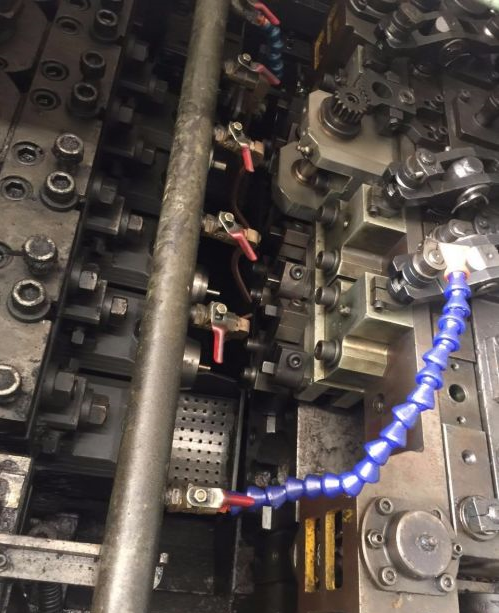

What About Quality Control?

We Have A Perfect QC System For The Perfect Products. A Team Who Will Detect The Product Quality And Specification Piece Carefully, Monitoring Every Production Process Until Packing Is Complete, To Ensure Product Safety Into The Container.