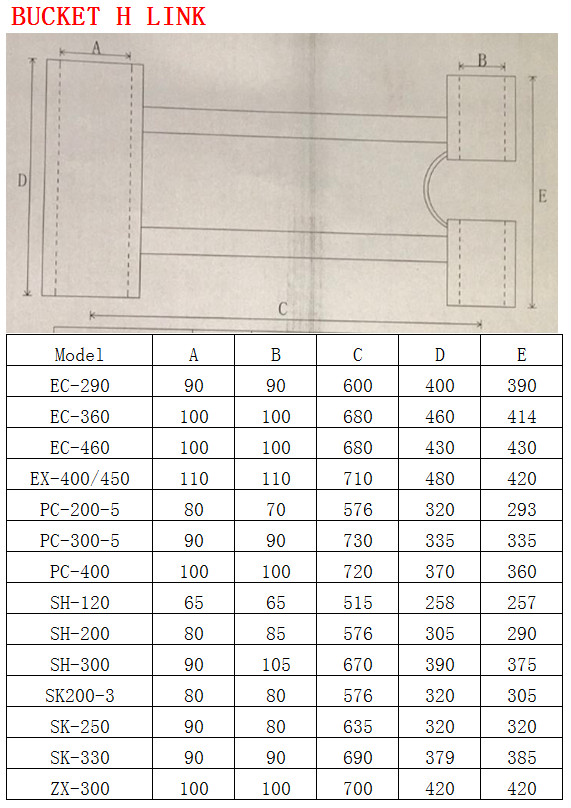

Bucket H-Link

1.Excavator's on BUCKET H-LINK structure, through the screw thread cooperate with seamless pipe connection, pin on seamless tube inserted in the interior of the bolt hole, to strengthen the structure of mild, set up the spring, absorb shock and earthquake, the purpose of art is to solve the current BUCKET H-LINK strength is not enough, easy to damage, increase the number of excavator maintenance and the maintenance cost and delay the progress of the excavator's normal use.

2.The two ends of the H-link bucket are respectively formed with the front and rear sleeve of the outer surface of the arc matching, h-link bucket and the front and back end of the sleeve welding combination, BUCKET H-LINK using forging can greatly increase the BUCKET H-LINK strength, arc joint surface can improve the force surface of BUCKET H-LINK and sleeve, and increase the combination strength of BUCKET H-LINK and sleeve, the support is arranged between the two connecting arms can further improve the overall strength of the frame.

3.By setting a chip groove, chip hole and sealing rubber block, easy to discharge the particles generated by friction on the inner ear, avoid the particles generated by friction on the inner wall of the ear is not easy to discharge, resulting in increased friction degree, improve the strength of the connecting rib plate, avoid bending damage after the connecting rib plate stress.

The utility model qiqiuchi frame is bonded by a movable joint and a connecting pipe socket, so that the direction of the joint can be flexibly adjusted. The movable joint can be properly rotated to different angles according to the installation needs, and the appropriate length of the connecting pipe can be selected according to the needs. It is not limited by the site, and the installation is convenient.When the customer needs, according to the user needs to cut the length of the connection pipe socket bonding.

| Description: | Bucket H-LINK |

| Place of origin: | China |

| Brand name: | PT'ZM |

| Model number |

|

|

|

|

| Price: | Negotiate |

| Packaging details: | Fumigate seaworthy packing |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 10000 PCS/month |

|

|

|

| Material: | Q345 |

| Technique: | Forging |

| Finish: | Smooth |

| Hardness: | HRC55-68 |

|

|

|

| Quality: | mining operation heavy duty high-end quality |

| Warranty time: | 24 monthes |

| After-sales service: | Video technical support,Online support |

| Color: | Black or Yellow or Customer required |

| Application: | Bulldozer & Crawler excavator |